GET A QUOTE

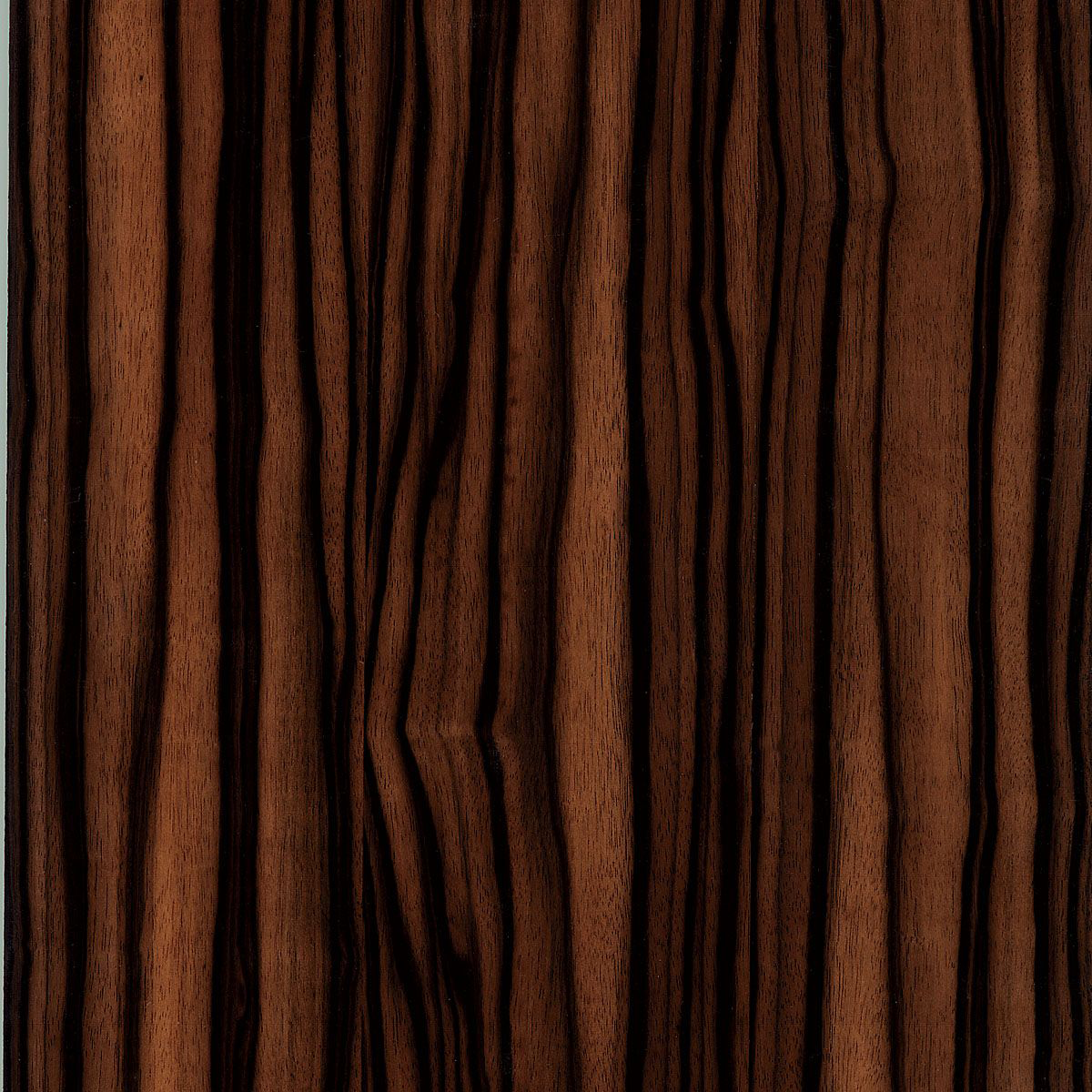

Custom Hardwood Veneer Faces

FormWood Industries will source and splice hardwood veneer faces to meet your specifications. We work closely with designers and architects to develop unique, cost-effective alternatives to applying nature's wood beauty to store interiors, elevators, lobbies, furniture, cabinets, and casework.

Features and Benefits

- Faces may be Book or Slip Matched

- Running, Balanced, Center-Balanced, or Blueprint Matching available

- Long grain material available in 4' x 8', 4' x 10', 4' x 12', 5' x 8', 5' x 10', and 5' x 12'

- Cross grain material available in 8' x 4', 10' x 4', 12' x 4', 8' x 5', and 10' x 5'

- Specific parts can be created to meet your needs on a repeating basis

- Custom faces available to fill your specific needs for one-time orders

- Quick lead times possible due to the vast flitch inventory maintained at FormWood's facility

- Flitch sampling available to allow you to specify the perfect log for your application

- Custom sizing up to 5'x12' possible for over 100 cuts and species of veneer

Technical Specifications

Information based on a 4'x8' sheet.

- Thickness: 1/28" - 1/40"

- Standard Size: 4' x 8'

- Maximum Size: 5' x 12'

- Shipping Method: Flat via LTL or dedicated carrier

- Minimums may apply

Storage

- Best to store in a climate controlled environment. (Heated in winter/Air-conditioned in summer.)

- Relative humidity of 35% is best.

- Avoid exposure to sunlight.

- Can be stored at least 12 months in dry and cool (15-25°C/58-76°F) conditions.

Color and Grain Appearance

- Variation can be expected from sheet to sheet and lot to lot.

- Sequence matching available upon request.

General Application Information

- Inspect material for satisfaction of quality and grade prior to lamination.

- All veneer should be acclimated prior to application.

- Ideal temperature for application is 70-80°F.

- Ideal humidity is 35%.

- Surface must be clean, dry and smooth (free of dust, grease, wax) to ensure a good bond.

- Veneer scrapers are recommended for hand application to allow for maximum pressure. "J" rollers are not recommended.

- Adhesive should be allowed to cure for 48 hours prior to finishing.